Repair method

Paintless Dent Repair (PDR)

is a method of removing dents from car panels by working on the dent from the underside of the panel. The dents are treated using special PDR tools to regain the panel's original smooth quality. Metal and paint are flexible materials and do not suffer any damage during the repair process.

This gentle repair process is meanwhile acknowledged and accepted internationally by most insurance companies and is generally the preferred method of repairing dents and hailstone damage.

Very high standard

Repairing vehicle damage of this nature should be left to the experts, as achieving the best results takes extensive specialist knowledge, a very keen eye, a range of special tools, years of professional experience, outstanding fingertip feeling and an inclination towards perfectionism.

The result of a successful dent or hailstone repair must always be untraceable, as if it had never happened or as if the panel were new.

There is a difference between a so-called Dent Doctor and a hailstone damage engineer. A busy Dent Doctor will remove between 10 and 20 dents per day, whilst a hailstone damage engineer has to cope with around 20 times as many repairs after an average hailstorm.

Pressure method

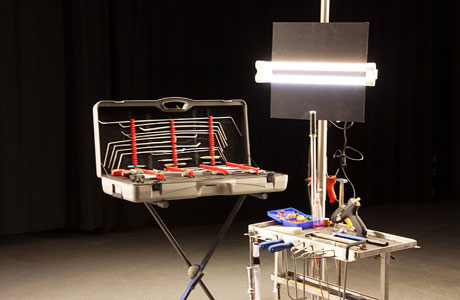

The pressure method involves pushing or massaging out dents that can be reached from inside the panel using a specially designed leverage tool. The method applies precise yet gentle pressure to dented panel area, leaving the paint structure intact. A special lamp is positioned above the area to be treated. The reflection caused by the dent makes it possible to work on the panel until its original condition is restored.

Adhesive method

This method involves attaching a pulling adapter over the centre of the dent using special glue that does not damage the paint. After the glue has set the adapter is pulled out using an impact hammer until a slight outward bulge is created. The bulge is then tapped back into the panel using a tapping pin until the panel's original form is restored. This method is used to repair areas that cannot be reached from inside the panel, for instance on roof edges or double-wall sections, and to avoid otherwise costly bodywork repairs.

Hammer method

The hammer method involves various hammering techniques that are used to treat larger dents caused by, for instance, manufacturing errors (roof wraps), accidents, roof avalanches or severe hailstorms. The panel is carefully struck in specific places to release tension in the material and restore the panel to its original form.

Germany's hailstone season lasts just a few weeks. Only a well-trained engineer accustomed to both national and international assignments has the experience and the necessary physical and mental stamina to repair hailstone damage to Hagelprofi quality standards.

If basic conditions are met, the future specialist will pass through a training phase of 3 to 4 years to acquire the skills needed to repair hailstone damage independently.

Fast-track training measures as are currently available from various training centres can at best be seen as trial apprenticeships or informational courses for the industry.

Hagelprofis Deutschland UG guarantee to exclusively provide engineers with long-standing professional experience or, in exceptional cases, engineers who are accompanied by a qualified trainer.

This guarantee extends to all services provided on behalf of Hagelprofis Deutschland UG.